Chaussette de salle blanche lavée Micronclean Grey

BlogSalle blancheEPI/TextilesDurabilitéMicronGreen24.10.2025

BlogSalle blancheEPI/TextilesDurabilitéMicronGreen24.10.2025

Advancing Cleanrooms Through Design, Validation, and Sustainability

Following almost two years of proven use of the original white laundered cleanroom sock, Micronclean has introduced the Grey Laundered Cleanroom Sock - an evolution that delivers equivalent cleanroom performance with enhanced sustainability and long-term appearance retention.

The new grey sock maintains the ergonomic fit, breathability, and moisture management of its predecessor but is now manufactured using over 65% recycled content. A grey colour was selected to minimise visible discolouration, supporting a consistent and professional appearance over the validated processing life. An embroidered Micronclean logo provides simple visual verification, improving traceability and compliance assurance within controlled environments.

Designed for Regulatory Compliance

Under EU GMP Annex 1 (Section 7.14), socks worn in Grade B and C changing areas must not introduce a contamination risk. The Micronclean Grey Laundered Cleanroom Sock has been tested and validated to meet this requirement.

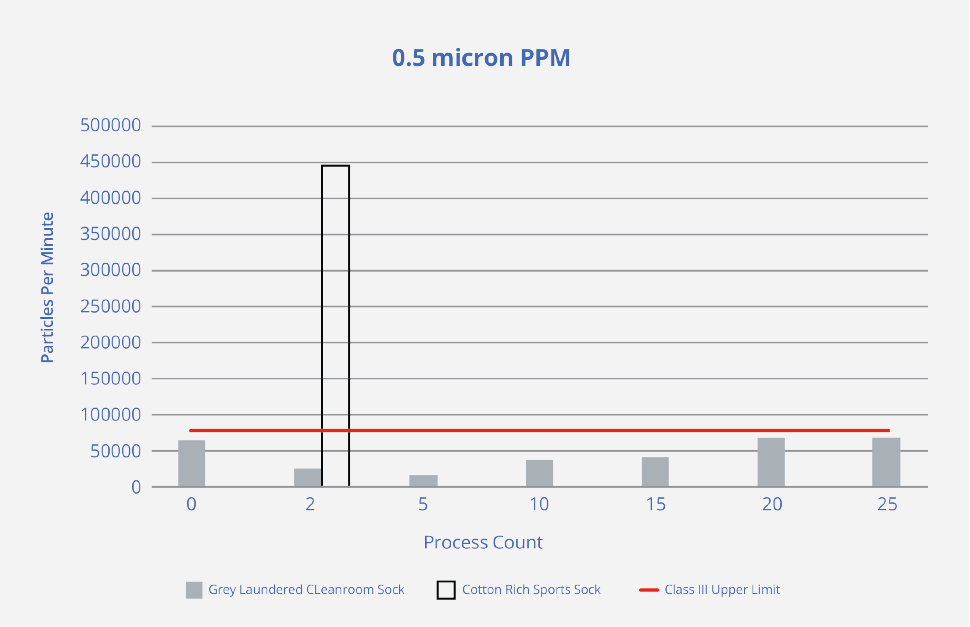

Testing in accordance with the Helmke Drum method (IEST-RP-CC003.5) confirmed:

- Category III garment particulate classification maintained for the full validated lifespan of 25 wash cycles.

- Significantly reduced particle release compared with typical white cotton-rich sports socks washed under domestic conditions.

This demonstrates that the laundered sock consistently performs at a level appropriate for use in controlled environments requiring low particulate contamination.

Dimensional and Visual Stability

Dimensional stability testing confirmed that the sock maintains a consistent fit following initial processing, ensuring wearer comfort and garment integrity throughout its validated life.

Colour retention testing showed no visible fading after 25 validated wash and dry cycles. The grey colour maintains a clean, uniform appearance, helping operators and auditors verify correct usage during compliance checks.

Sustainability in Practice

Transitioning from single-use disposable socks to Micronclean’s laundered model provides a 96% reduction in landfill waste over equivalent usage.

Where disposables are worn once and discarded, the reusable laundered sock remains compliant and comfortable for 25 validated process cycles.

Material Composition

The material composition has been optimised to balance comfort, performance, and sustainability:

- 65.3% Recycled technical fibre (post-consumer plastic derived)

- 21.7% Polyester

- 6% Nylon

- 4% Elastic fibre

- 3% Caoutchouc

The technical fibre provides effective breathability and moisture management, maintaining skin comfort while meeting the durability requirements for cleanroom use. The use of recycled fibre supports Micronclean’s wider commitment to the principles of a circular economy.

Conclusion

The Micronclean Grey Laundered Cleanroom Sock represents a validated, sustainable, and operator-friendly solution for all controlled environments. Combining proven cleanroom performance, reduced environmental impact and durability through 25 validated process cycles, it supports facilities seeking to balance contamination control with measurable sustainability outcomes.

Auteur

Marta Underwood

Cleanroom Textile Group Product Manager